Sustainability innovations at Texhibition Istanbul Fabric, Yarn and Textile Accessories Fair

Having attended the sixth edition of Texhibition Istanbul Fabric, Yarn and Textile Accessories Fair on 11-13 September 2024, we take a closer look at some of the exhibitors and their sustainable products.

Turkey cannot compete on price with countries such as Bangladesh, Pakistan and Vietnam, so it is capitalising on its strengths – a key one being sustainability. It has recognised the need for a more cooperative, holistic approach, with innovative thinking and the sharing of information and resources that will ultimately help the whole industry.

A central display, Hall of Impact, showed the following areas of exhibitors’ endeavours.

Resource efficiency: Reducing water usage by 50%, purifying it, and returning clean water to the environment. Eco-friendly innovation: Adopting renewable energy sources and creating more efficient supply chains for raw materials. Lowering CO2 emissions: Cutting carbon dioxide emissions by 50% to combat climate change. Digital design: Embracing 3D technology to reduce fabric waste, enhance production efficiency, and foster creativity. Digital Innovation in operations: Increasing online activities to lower emissions for a greener world. Social Responsibility: Ensuring fair labour practices and prioritising worker safety to contribute positively to communities.

Several companies have vertical production, meaning they can trace product through the production cycle in cotton yarn and denim, from raw material to dyestuff and processing. As well as the show’s Yarn Area expanding to include 41 exhibitors, the BlueBlack Denim hall featured 25 companies, including Bossa, Iskur Denim and Kipaş.

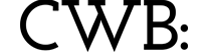

Bossa

Established in 1951, Bossa is one of the largest integrated textile companies in Turkey. With a high production capacity in dyeing and finishing, it implements a wide range of eco-friendly raw materials, dyestuff and processing initiatives throughout the production cycle. It is also certified by Oeko-Tex 100, Global Organic Textiles Standard (GOTS), Organic Exchange 100 & Blended, Global Recycle Standard (GRS), and ISO 14001 (Global Cert). For a/w 25/26 it is introducing the Endless Blue fabric collection made with the regenerated virgin cellulose fibre SaXcell derived from chemically recycled cotton waste.

Iskur Denim

Iskur Denim is another vertical supplier of yarn as well as fabric and manufacturing, enabling a completely circular approach when it comes to its products. It has introduced ‘zero cotton + Tencel fibre’. Instead of raw cotton, it uses pre-consumption or post-consumption cotton and Tencel fibre, which is produced by using sustainable water and soil resources. Pre-consumer waste is collected from all the textile factories in the Iskur Group, classified, torn, and recycled again into fibre. It has also implemented a water-saving process that uses 95% less water in its indigo dyeing, as well as using the natural energy sources of solar and wind.

Kipas

Blue Shirt fabric: a reuse story by Kipas. Using CIRCULOSE’s innovative technology allows the separation of used textiles into their basic fibres, enabling the reproduction of pure cellulose. This process significantly reduces the need for virgin materials, decreasing water usage, energy consumption and greenhouse gas emissions. Using a blend of PRCO (post-consumer recycled organic) and PCW (post-consumer waste) materials, it transforms discarded textiles into high-quality materials.

Established in 2019, Karafiber is Turkey’s first Lyocell fibre producer.

Karafiber aims to reduce more carbon from the atmosphere than it produces in the areas in which it operates. Among other things, its Ecocell Lyocell fibre comes from sustainably grown wood and is produced in a closed cycle to conserve resources. Lyocell is slowly gaining popularity for its softness, absorbency and most significantly, as a more ethical and sustainable fibre alternative to silk or cotton. (Regarding the latter, Lyocell has the potential to use less than half as much water in production.)

Since 1971, SÖKTAŞ has been passionate in its support of the artistic and cultural heritage of its region. As well as being a regenerative cotton producer, it takes on many R&D projects, including the development of a brand-new variety of cotton. A long-term project undertaken in partnership with the Cotton Research Institute of Türkiye has culminated in a new plant that produces exceptionally strong, fine and silky fibres.

Elsewhere, Aydin Örme presented its LilacellLace, an innovation made with the cellulose fibre Lyocell from Tencel and fabrics produced from recycled nylon. The woollen fabric producer Bahariye from Istanbul is officially committed to sustainable, social and environmentally friendly production and can boast numerous certificates. Polyester fibre manufacturer Korteks has also achieved a breakthrough in Turkey with its Polymer Recycling Plant producing polyester yarns from plastic bottles.

Two of our favourite trims companies with sustainable innovations: YKK and Isik Etiket.

YKK has developed the first recycled mono-material detachable button as a solution for circularity. YKK Detachable Accessory is a versatile, eco-friendly solution designed for easy attachment and removal, combining durability with minimal environmental impact through sustainable materials and responsible manufacturing practices. As well as simplifying the removal of metal trims it reduces the metal trim-based fabric waste to zero.

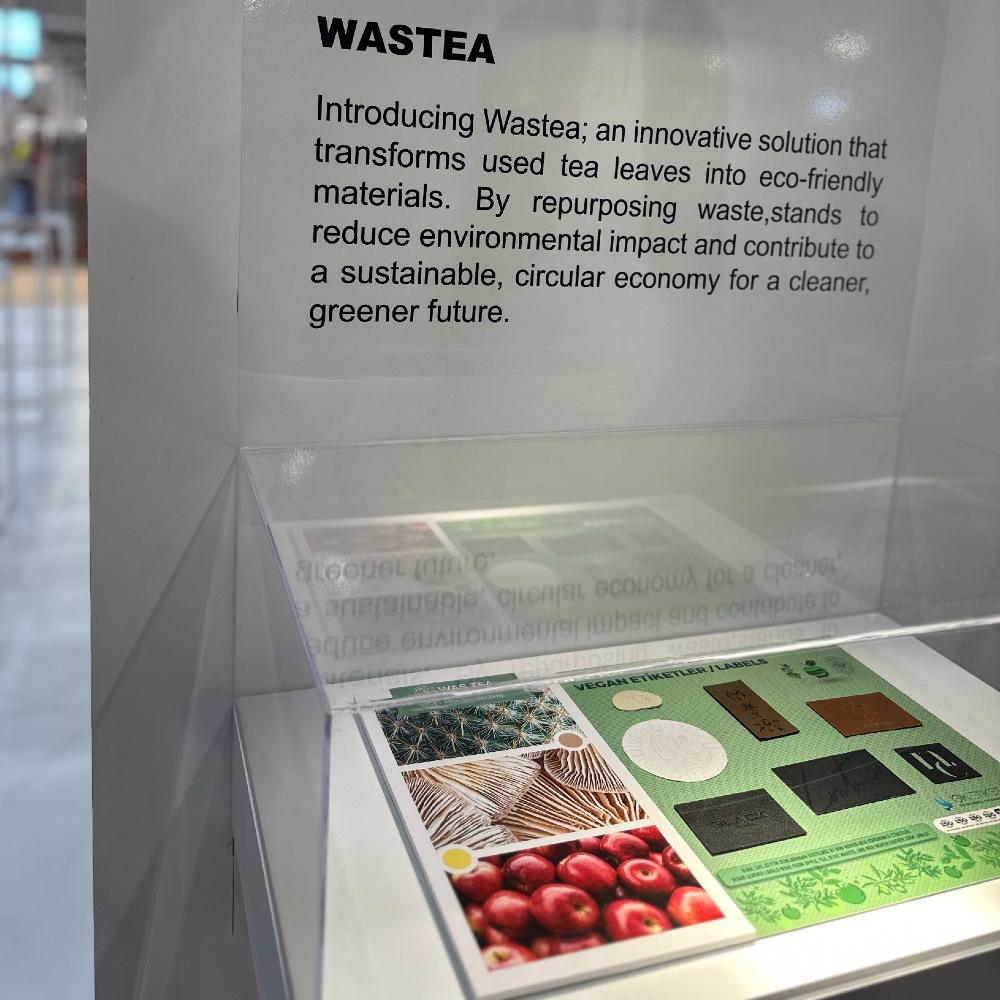

Label and packaging manufacturer, Isik Etiket, is based in Merter, Istanbul. It has an extensive range including several products using recycled materials and innovative zero-waste concepts. Some of our favourites are the Wastea labels, an innovative solution that transforms used tealeaves into eco-friendly materials. Produced from industrially processed tea waste, it is 100% sustainable, vegan, bio, and plant-based. Apple skin leather labels, meanwhile, are produced using fibres obtained from industrially processed apple skin. These labels are ecological, environmentally friendly and animal-friendly, significantly reducing energy emissions and consumption.

Compostable and biodegradable packaging includes seed paper tags made from recycled paper and filled with specific seed varieties. By planting your seed paper tags into the soil instead of discarding them, you actively contribute to a sustainable future, helping prevent environmental pollution and adding value to your product. The company has won awards for its zero-waste products, including the woven card holder as an alternative to swing tags, which is designed to be used as a cardholder after removing it from the product.

Texhibition Istanbul Fabric, Yarn and Textile Accessories Fair will return on 5-7 March 2025. For further information, please click here.